Upgrade packhouse operations with quality, precision, efficiency, and scalability

Automate sorting, packing, and inventory tracking to reduce costs, enhance quality, and meet global compliance standards.

Overview

Seamless processing, smarter operations, maximum efficiency

ProcessPack10X streamlines post-harvest operations, from arrival to dispatch, so your packhouse runs faster, leaner, and more profitably.

It automates quality checks, packaging, cold chain, and inventory movement to eliminate errors, reduce waste, and ensure compliance. With real-time visibility and deep insights, it helps you scale operations, meet global demand, and maximise every shipment.

Ideal for :

Challenges in Contract Farming

What makes post-harvest management difficult

Low profit margins

Cost leakages across procurement, operations, and logistics eat into earnings.

Poor forecasting & visibility

Inaccurate demand planning and material shortages disrupt workflows.

Underused capacity

Manual coordination leads to low production efficiency and resource wastage.

Limited Real-Time Visibility

No live tracking of operations leads to delays and uninformed decisions.

Time-critical operations are hard to manage

Sorting, packaging, cold chain, and dispatch lack speed and sync.

Returns & rejections due to quality issues

Inconsistent quality checks and errors in packaging affect customer satisfaction.

Supply chain & logistics inefficiencies

Delayed order processing, poor vehicle capacity usage, and logistics gaps slow down fulfilment.

Inventory mismanagement

Overstocking, wastage, and valuation errors raise costs and cause write-offs.

No end-to-end traceability

Lack of batch-level traceability makes audits and recalls difficult and slow.

Disconnected data & manual reporting

Poor data capture and a lack of integration prevent timely decisions.

Sustainability pressures

High carbon footprint, water wastage, and poor waste handling hurt long-term growth.

Features That Solve These Challenges

How FarmERP ProcessPack10X addresses these challenges

-

Planning & production

-

Procurement & resource allocation

-

Post-harvest operations

-

Inventory management

-

Sales & Distribution (O2C)

-

Traceability & recall preparedness

-

Quality control

-

Governance & real-time visibility

-

Mobility, IoT & data integration

-

Sustainability

Planning & production

- Sales, production, and material requirement planning

- Production orders and work-out reports

- Plan vs. actual reports for better capacity utilisation

Procurement & resource allocation

- Vendor selection and purchase management (P2P)

- Budget tracking and resource planning

- Requisition and quotation workflows

Post-Harvest Operations

- Material receipt and weighment

- Quality checks at arrival, in-process, and pre-dispatch

- Primary and secondary packaging

- Palletisation and cold chain management

Field Operations

- Activity Scheduling & Calendar View

- Machinery & Input Allocation

- QR Codes for Field, Labour, Machinery

- Harvest Tracking, Tree-Wise Data

- Crop Protocols & Field Observations

- Field Data via Mobile App

Sales & distribution (O2C)

- Sales booking, invoicing, and return management

- Retail and wholesale support

- Logistics management, vehicle loading and capacity optimisation

- Mobile app for sales teams

Traceability & recall preparedness

- Lot-level traceability from arrival to dispatch

- F-QR codes for finished goods

- Fast recall tracking and audit support

Quality control

- Configurable checks across all stages

- Customer-specific packaging and labelling

- Mobile-based quality data capture

Governance & real-time visibility

- Executive dashboards for performance and alerts

- Centralised record keeping

- Daily progress monitoring

Mobility, IoT & data integration

- Native mobile apps for field operations

- Single sign-on and offline data sync

- IoT integration for real-time data capture

Sustainability

- Waste management and carbon tracking

- Efficient packaging and resource usage

- Water usage monitoring

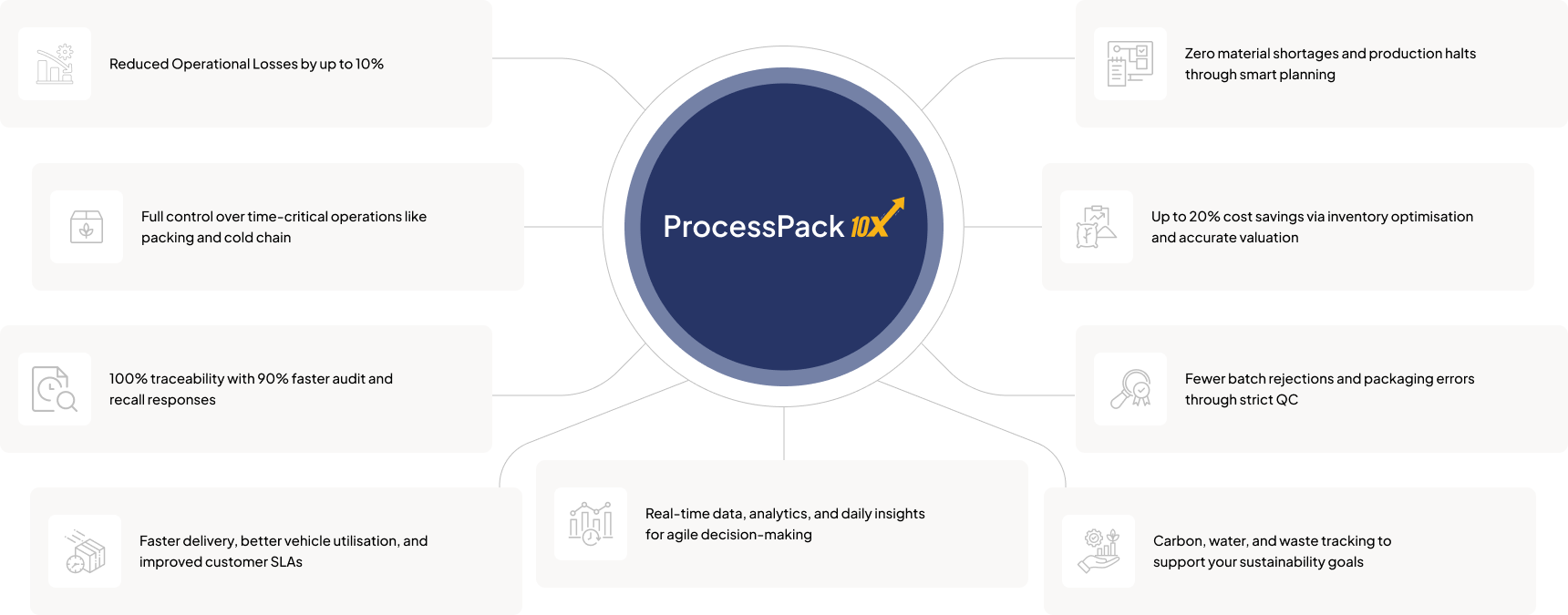

Benefits of ProcessPack10x Features

What You Gain with FarmERP ProcessPack10X